南湖新闻网讯(通讯员 刘世伟)近日,我校工学院农产品智能检测及数字化装备团队刘世伟副教授、王巧华教授在IEEE Transactions on Industrial Informatics杂志在线发表了题为“Hybrid Conditional Kernel SVM for Wire Rope Defect Recognition”的研究论文。该研究报道并提出了一种新的混合条件核SVM机器学习分类器模型,揭示了该模型的数学可靠性、分类可行性、定量化无损检测可靠性以及广阔的应用前景,该方法可望替代现有传统支持向量机分类器,并推广至工程学、信息学、生物学等多学科领域。

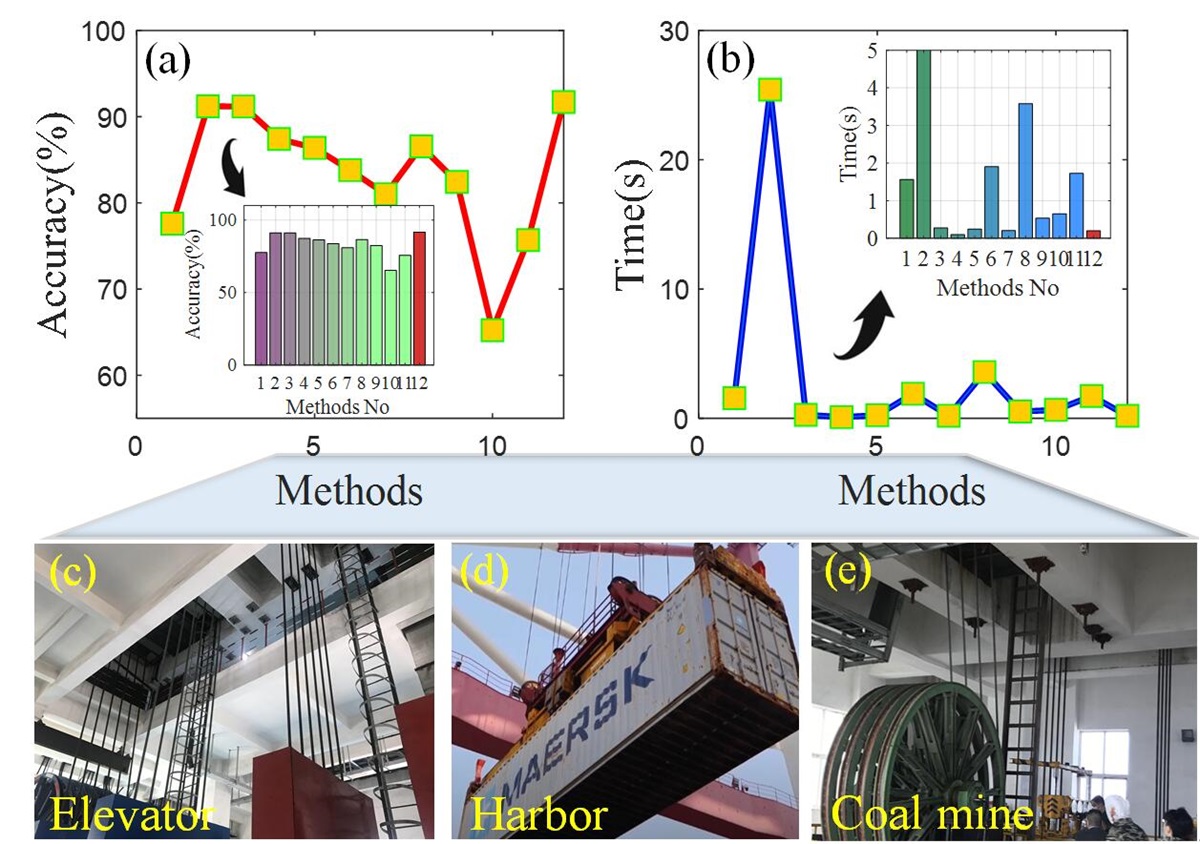

该研究首次提出一种基于双曲正切和指数函数新型混合条件核SVM支持向量机-机器学习分类模型,通过构建基于混合条件核函数的缺陷检测SVM分类器模型,结合数学证明,揭示了新的核函数正定性、收敛性及复杂度等特性,结合15种不同的验证数据集、12种典型常规核函数以及LSSVM、TWSVM等相关最新机器学习模型对比测试,验证了混合条件核函数SVM模型的有效性及缺陷分类与定量化识别优势;揭示了混合条件核函数SVM模型参数对分类器分类结果影响规律,通过复杂场景下直径22mm (6×36sw), 28mm(6×25fi), 36mm(6k×36sw)等多规格型号钢丝绳样件,以及运行速度为0.5m/s, 3m/s等工况下的缺陷检测实验和数据集分类,获得了5种不同缺陷定量化分类结果,其总体分类准确率可达91.7%,该算法在线识别运行时间小于0.2s。最后,结合典型场景下的钢丝绳缺陷检测应用案例,进一步证实了混合条件核SVM的可行性和广阔应用前景,该方法可望推广至无损检测、人工智能、信息学等领域。

(a) Recognition accuracy; (b) Recognition time; (c)-(e) Typical application scenes.

混合条件核SVM分类性能对比及应用

华中农业大学工学院农产品智能检测及数字化装备团队刘世伟副教授为该论文的第一/通讯作者,王巧华教授指导参与了该项工作并给出宝贵建议,工学院2022级硕士研究生刘勇、2023级硕士研究生单龙祥以及合作单位华中科技大学机械科学与工程学院孙燕华教授、何岭松教授等共同参与了该研究工作,华中农业大学为第一完成单位。该工作得到国家自然科学基金、湖北省自然科学基金、中央高校基本科研业务经费以及电磁能技术全国重点实验室基金的资助。

英文摘要:

Support vector machine (SVM) has been applied in data classification and defect recognition in various scenes, the common kernels are not always suitable to satisfy the requirement of high accuracy and efficiency inspection. A new hybrid conditional kernel (HCK) and SVM model based on exponential functions is proposed in this article, the validity and feasibility of the basic characterizations are introduced theoretically first, and the numerical classification results for different datasets are calculated and compared with related algorithms. Then, the performance evaluation of the new model from the perspective of kernel parameter investigation, statistical data analysis, and experimental verification are conducted, and the wire rope defect inspection sample sets are built according to features extraction and eigenvalues computation. Finally, the comparison results where the new HCK based SVM can reach almost the highest classification accuracy of 91.70% and least running time of 0.1968 s for five different wire rope defects among 12 machine learning models not only prove the superior performance of the proposed method in wire rope defect recognition, but also show great promise in high precision classification in other application fields. The limitations of this model and future work are also discussed.

审核人:王巧华